By Ashley Burkle, Director, Sales and Business Development at Identiv.

Manifest 2026 convened senior leaders from CPG, grocery, retail, and logistics to address a clear mandate – how to deploy AI, automation, and IoT technologies in ways that measurably improve supply chain performance. Discussions centered on system integration, data reliability, interoperability, risk reduction, and return on investment.

Below are the five defining trends that emerged from this year’s show – and what they indicate about the next stage of supply chain intelligence.

- AI Embedded Into Core Operating Systems

Artificial intelligence is now built directly into transportation management, warehouse management, and visibility platforms. Routing systems recalculate shipment paths in real time based on traffic, weather, and capacity constraints. Inventory platforms adjust replenishment quantities using live demand and sell-through data. Yard and warehouse systems use machine learning to sequence work and increase throughput.

As AI becomes embedded in these operational systems, its performance depends on the accuracy of physical-world data. Reliable information on product identity, asset location, environmental condition, and chain of custody determines the quality of automated decisions.

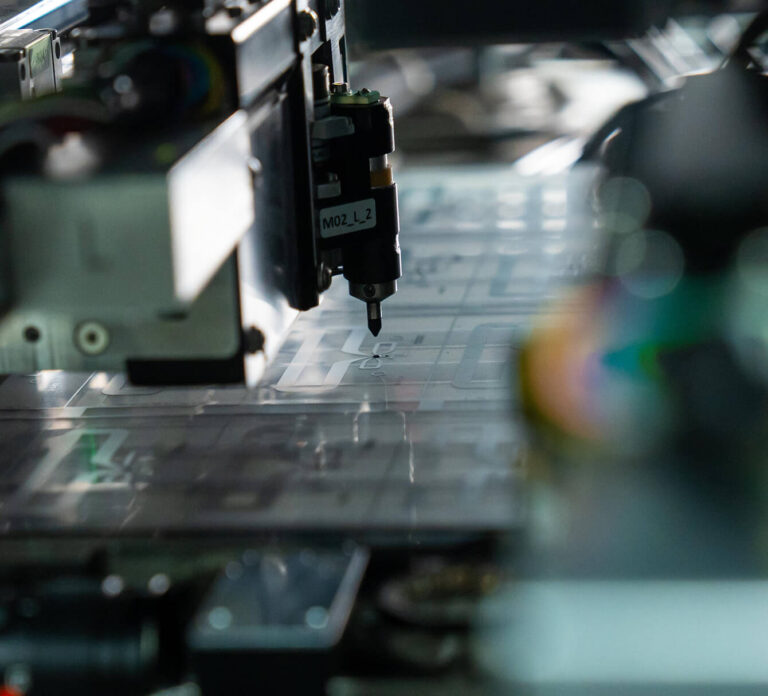

RAIN RFID, BLE-enabled sensing, and secure IoT infrastructure provide this data foundation. Authenticated tags and inlays ensure that each product or asset carries a verifiable digital identity. Companies such as Identiv, which design and manufacture secure RFID and IoT-enabled identification solutions, operate at this foundational layer – enabling AI systems to act on trusted data.

- Robotics Integrated Across Multi-Site Networks

Robotics adoption continues to expand across fulfillment and distribution centers. Autonomous mobile robots transport goods across facilities. Robotic picking systems increase order accuracy and throughput. AI-enabled sortation systems optimize flow.

The focus has shifted to integration. Robotics platforms are being aligned with warehouse systems, transportation schedules, and labor management tools. Enterprises are designing coordinated operating environments in which physical automation and digital systems function as a unified network. Performance gains depend on synchronization across facilities rather than isolated automation projects.

- Cold Chain Monitoring Embedded Into Operations

Temperature-sensitive supply chains in food, biologics, and pharmaceuticals are under heightened regulatory and brand scrutiny. Continuous environmental monitoring is now built into distribution models.

Real-time temperature and condition sensors track goods across storage facilities, trailers, and last-mile delivery. RFID and BLE-enabled sensors link environmental data directly to individual products. This enables traceability, audit readiness, and rapid exception management. Secure digital identity ensures that temperature and condition data remains attached to the correct product throughout transit.

- Platform Interoperability and Persistent Digital Identity

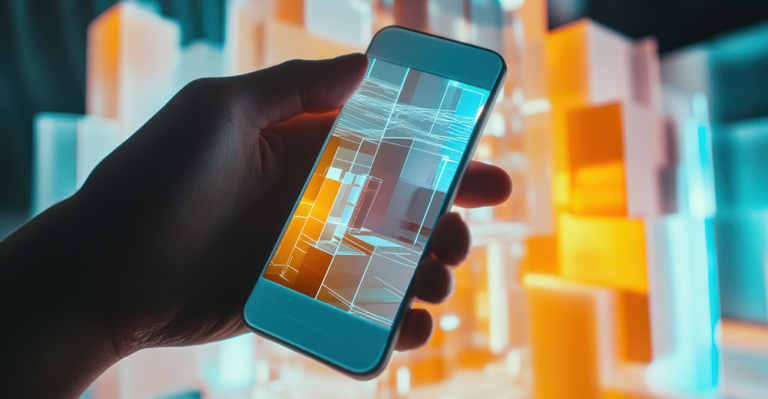

Enterprise supply chains operate across ERP, WMS, TMS, yard management, labor systems, and IoT platforms. Data fragmentation reduces visibility and slows decision-making. Interoperability was a consistent theme throughout the show.

Unified data models and API-driven integration strategies depend on persistent digital identifiers. UHF (RAIN), NFC / HF, and BLE technologies allow products and assets to maintain consistent, platform-readable identities across systems and lifecycle stages. This persistent identity enables accurate reconciliation, reporting, and automation.

In 2026, platform interoperability remains a central priority. Businesses are working to ensure that data captured across multiple systems converges into a unified operational view rather than remaining siloed across disconnected platforms.

- Asset Protection and Real-Time Visibility

Cargo theft and organized fraud continue to impact high-value shipments. Enterprises are deploying real-time location tracking, geofencing, tamper detection, and anomaly monitoring to reduce exposure.

Persistent asset identity and continuous condition monitoring strengthen chain-of-custody documentation and support insurance and compliance requirements. Visibility supports operational performance, regulatory adherence, and risk mitigation simultaneously. Secure digital identification underpins each objective.

Designing the Next Phase of Supply Chain Intelligence

Manifest 2026 demonstrated that AI, robotics, IoT sensing, and data integration are being deployed as interconnected capabilities across supply chain networks.

The next stage of supply chain advancement will depend on how effectively organizations align these technologies across systems, facilities, and product lifecycles. Secure digital identity, real-time sensing, and interoperable data frameworks allow intelligence to travel with goods – capturing location, condition, movement, and custody at each stage.

Organizations that embed verified, real-time data directly into the physical flow of products will define the benchmark for visibility, control, and sustained performance in the years ahead.