As IoT systems mature, the physical tags, labels, and inlays that power them are being asked to do far more than identify an object or report a location. They’re increasingly expected to sense temperature, humidity, shock, light exposure, or environmental conditions – and to do so accurately, repeatedly, and for years at a time.

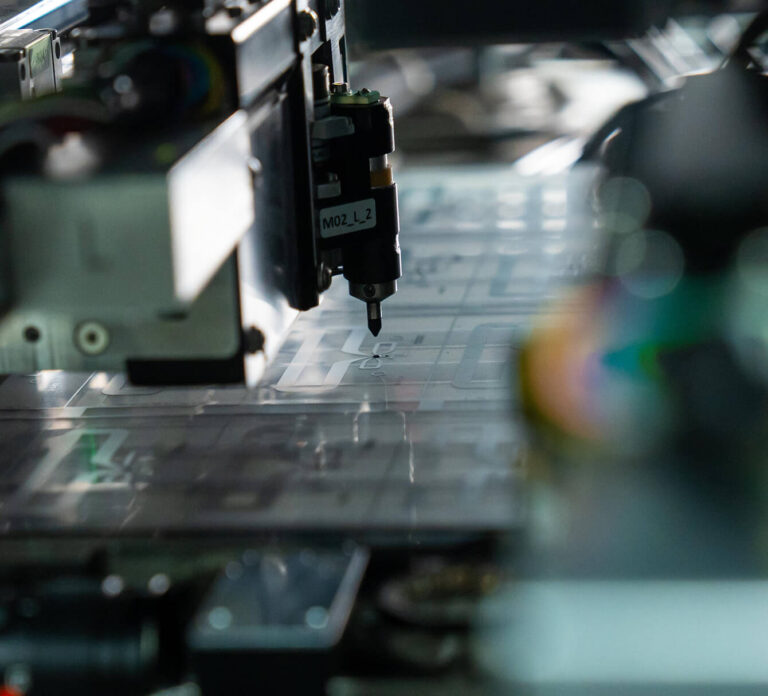

Delivering that level of performance changes the nature of the device itself. What once consisted of an antenna and a single chip has become a compact electronic system assembled on a flexible substrate. Manufacturing these systems reliably, at industrial volumes, is the central challenge now shaping the next phase of IoT.

That challenge – and opportunity – is multicomponent manufacturing.

When IoT Devices Became Electronic Systems

Early RFID manufacturing was built around elegant simplicity. A chip was bonded to an antenna, and production lines moved at extraordinary speed. That architecture worked because requirements were narrow and forgiving.

As applications expanded into healthcare, logistics, authentication, and condition monitoring, additional functionality became essential. External capacitors stabilized performance. Crystals enabled precise timing. Sensors captured environmental data. Batteries and energy sources extended operational life.

Each added component increased both capability and complexity. The question was no longer whether these systems could be designed – but whether they could be manufactured at scale, with consistent yields and predictable cost.

Identiv was among the first companies in the IoT industry to confront that question directly.

A Decade of Process Engineering, Refined in Production

Identiv began developing multicomponent manufacturing capabilities more than a decade ago, when early customer requirements exceeded what single-component RFID assembly could support. At that time, dedicated multicomponent assembly lines did not yet exist for roll-to-roll IoT production.

Our engineering team adapted existing equipment, introducing additional passive components through multi-pass workflows and tightly controlled process parameters. These early programs established foundational knowledge – how placement tolerances affect electrical performance, how substrates respond to mechanical stress, and how in-line testing must evolve as complexity increases.

Over time, this work expanded across consumer electronics, brand authentication, BLE devices, and multi-sensor-enabled tags – each program reinforcing the same underlying discipline. Tens of millions of multicomponent devices later, Identiv has accumulated a depth of production experience that no organization in the IoT ecosystem can match.

What Multicomponent Manufacturing Actually Requires

Multicomponent manufacturing is an exercise in coordination. Product design, process engineering, materials selection, equipment configuration, and in-line testing influence one another continuously.

A change in battery chemistry affects lamination and curing profiles. A new sensor alters antenna geometry and test thresholds. Higher throughput places tighter constraints on placement accuracy and defect classification. Each decision propagates across the line.

Identiv’s advantage lies in having navigated these tradeoffs repeatedly – across multiple component architectures, power models, and application environments – for over a decade and long before MCM became a baseline requirement for BLE and advanced IoT devices.

Thailand: A Facility Designed for Advanced MCM at Scale

Identiv’s Thailand manufacturing facility concentrates this expertise into a single, highly optimized production environment. Following a multi-year transition, the site now serves as the company’s primary hub for advanced RFID and BLE manufacturing, including high-complexity multicomponent assemblies.

The facility brings together modern multicomponent equipment with engineering and production teams carrying years of process knowledge forward from earlier Identiv manufacturing operations. Equipment configuration, parameter tuning, quality control, and reliability testing are integrated end-to-end to support high-mix, high-value products at scale.

This combination – advanced equipment paired with deeply embedded cross-functional manufacturing expertise – allows Identiv to commercialize new designs efficiently, even as component counts rise and durability requirements tighten.

Manufacturing as the Constraint – and Enabler – of IoT Innovation

As IoT devices evolve into long-lived sensing systems, manufacturing precision increasingly determines what data can be trusted upstream. Accuracy, longevity, and reliability are established on the production line long before software ever sees the signal.

Multicomponent manufacturing operates largely out of view, yet it defines the boundaries of what connected systems can achieve in the real world. As use cases demand more complex functionality within simpler, smaller form factors, manufacturers must deliver greater flexibility and specificity – without sacrificing production speed or cost targets that determine whether IoT adoption is viable at all.

Identiv’s early investment in MCM, and its continued leadership through experience and execution, position it to meet that crossover point: where advanced requirements still meet the cost thresholds required to justify changes in customer workflows.

That work continues every day, one component, one process adjustment, and one production run at a time.