Our CAPABILITIES

Specialized IoT Solutions That Fit Like They Were Built for You. Because They Were.

At Identiv, we don’t just manufacture inlays and labels – we design intelligent solutions. Our services go beyond standard RFID or BLE offerings to deliver custom-built, precision-engineered inlays and labels that solve your toughest challenges. Whether you’re tracking medication, ensuring food safety, or building smart, connected devices, our job is to make your job easier.

What we offer

Specialized

Design

Services

Antenna

Engineering

Encoding and Security

Printing and

Labeling

Manufacturing

Excellence

Specialized Design Services

Our core strength lies in solving complex use cases with specialized IoT inlays and label designs. From ultra-small footprints to on-metal applications, tamper-proof tags and multi-component manufacturing, we deliver form factors and functionality that fit and perform in the real world.

- Ultra-compact or unusual form factors (e.g., curved, rigid, on-metal, high-temperature)

- Dual-frequency capabilities: NFC+UHF RFID; BLE+NFC (HF); BLE+UHF

- Sensor integration (temperature, humidity, shock, strain, capacitive)

- Embeddable designs

- Broad expertise in leading chipsets and custom antenna designs, optimized for each unique use case

- Proven performance in critical environments such as healthcare, pharma, and food logistics

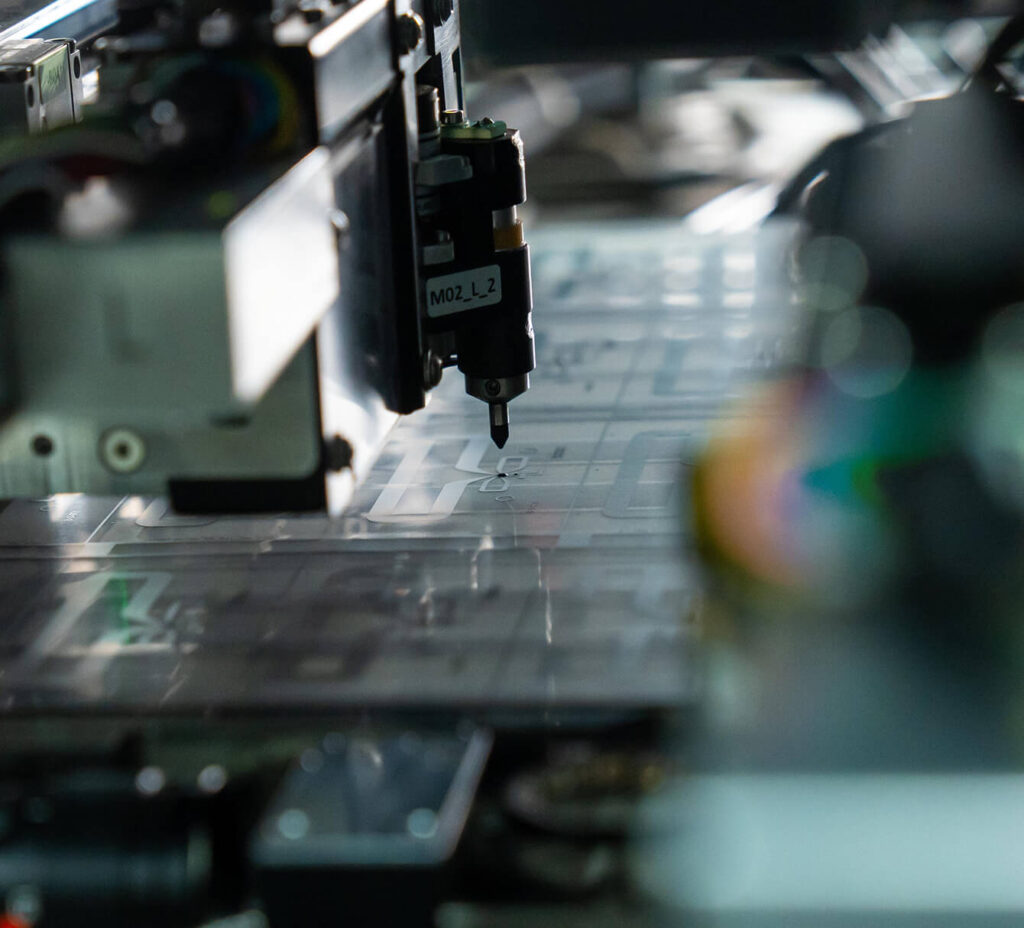

Antenna Engineering

Our expertise spans flexible, multi-component inlays and customized antenna designs, supporting virtually every major chipset from NXP, Wiliot, Infineon, STMicroelectronics, EM Microelectronic, InPlay, Asygn and beyond. This includes strategic collaborations with NXP, ST Microelectronics, Wiliot and InPlay. We were the first company to have built high-complexity Wiliot-based Gen2 and Gen3 BLE labels at scale.

- Custom antenna design

- High-performance antenna engineering

- Flexible circuits—label-convertible or encapsulated

- Ink and metal layer integration

Encoding and Security

We meet the highest standards in encoding and key management, delivering robust security that combats counterfeits and prevents unauthorized access. This commitment allows us to safeguard your assets with encrypted data and tamper detection, while precisely tracking every item’s unique journey from factory to customer.

- Custom data loads (ISO, GS1, industry-specific schemes)

- Secure tag commissioning using HSMs (Hardware Security Modules)

- On-premise key handling for encrypted tags

- Serialization, authentication, and anti-counterfeiting protocols built in

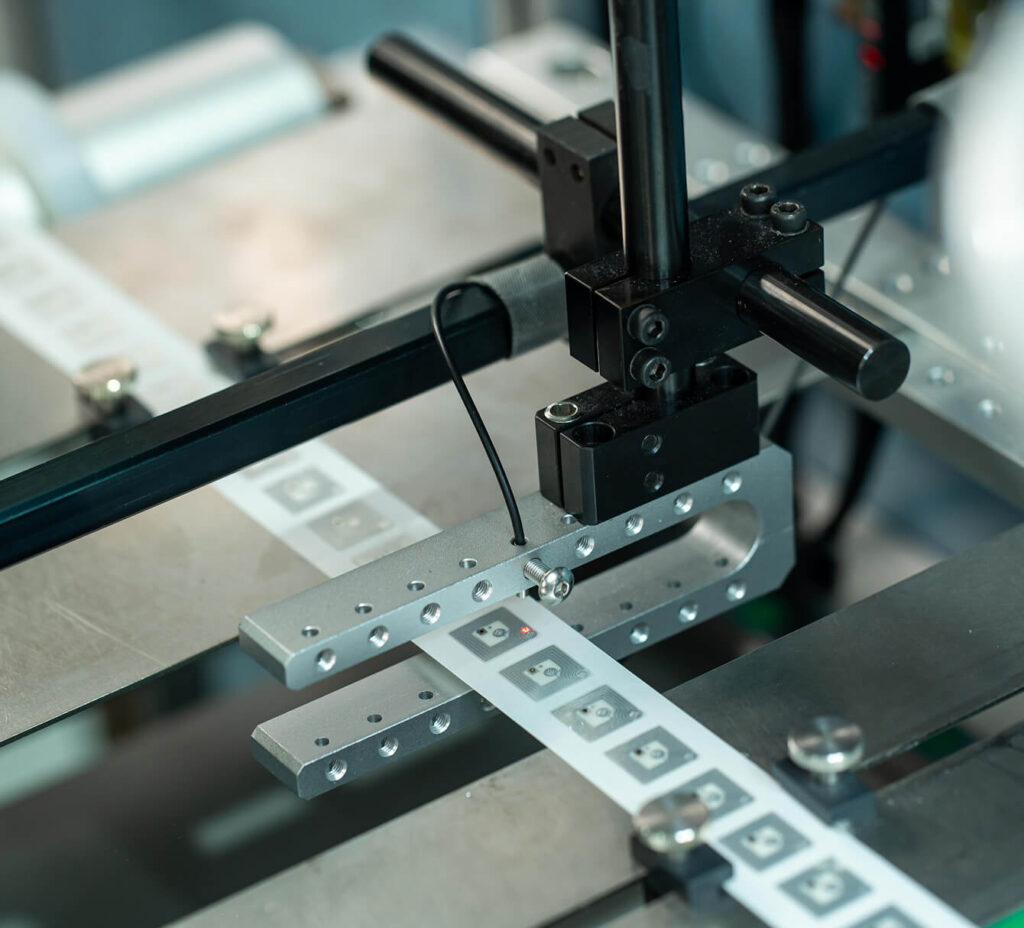

Printing and Labeling

Need more than a dry or wet inlay? We offer finished labels that are print ready and compatible with a wide range of common printing methods, ensuring maximum flexibility for your unique requirements. For projects that demand something extra, we offer premium artwork labels. Through our trusted partners, we can source high-quality printed face materials and provide special converting solutions to bring your vision to life.

- Custom artwork, barcodes, QR codes, and human-readable data

- 1-color monochrome or 4-color CMYK process printing services

- Serialization printing and variable data

- Domed tags that offer a protective three-dimensional look

Holograms and other distinctive features

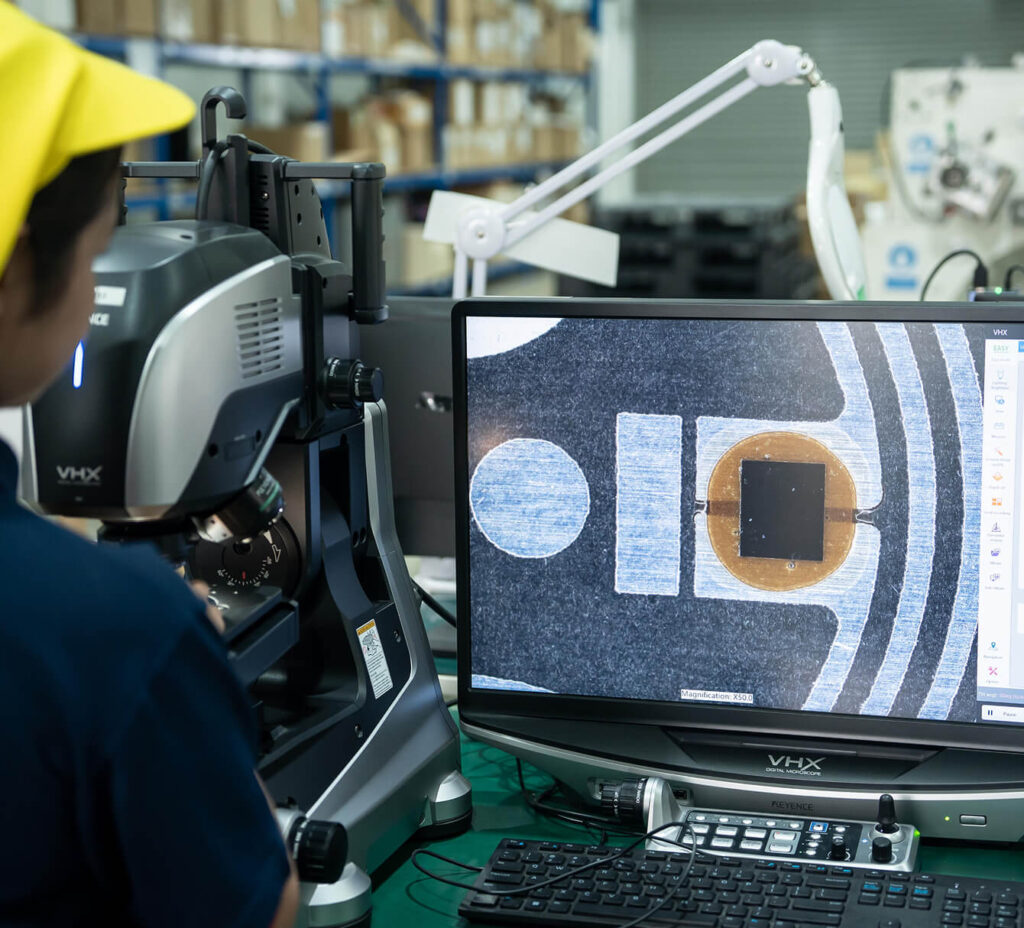

Manufacturing Excellence

Whether you need a short run or a global rollout, Identiv supports your production requirements with manufacturing processes proven at scale. We partner with you from design and prototyping through pilot validation, applying deep multicomponent manufacturing expertise to ensure a predictable, seamless path to full-scale mass production.

- Mass production capacity (hundreds of millions annually)

- ISO 9001:2015 and ISO 14001:2015 certified operations

- 100% inline quality testing